Wear plates for sale

Wear plates specifications

Our wear plates for crushers, chippers, shredders or grinders are characterized by long service lives and a constant wear profile. Request your (non) original wear plates (liner plates) in different thickness and steel alloys on this page.

Complementary items to order if needed:

- Hexagon head screws

- Hexagon nut

- spring lock washers with square ends

- conical spring washers

- plain washer without chamfer

- Plow bolt

- counter sunk screw with cam / square head

- Nord-Lock lock washer

- prevaling torque hexagon nut, with plasting insert

- Liner plates inlet

- Impact plates

- Blow bars

- Blow bar locking device

- Monoblock

- Apron

If you can not find the right items, please let us know in the request!

Looking for replacement parts for your recycling machine? We offer a comprehensive selection of wear plates compatible with equipment from major brands like: Metso, Sandvik, SBM, Keestrack, Terex Finlay, Terex Pegson, Powerscreen, Nordberg, Kleemann, Hammel, Arjes, Doppstadt, Lindner, Vermeer, Zemmler, Eschlböck, Komptech, Terex Ecotec, Terex Evoquip, McCloskey, Anaconda, Telestack, Backers, Eggersmann, Haas, Terra Select, Siebotec, Hartl, Hazemag, MFL, Rockster, Extec, Gipo, Lippmann, Parker, Portafill,

Prall-Tec, Rubble Master, SBM Wageneder, Svedala, Tesab, Rev, Tana, Untha, Zenith, Nordmann, Morbark, Gipo

FAQ – Recycling Equipment. Also read our FAQ about the different types of crushers, screeners, shredders and chippers.

Wear Plates for Crushers, Shredders, Grinders, and Chippers

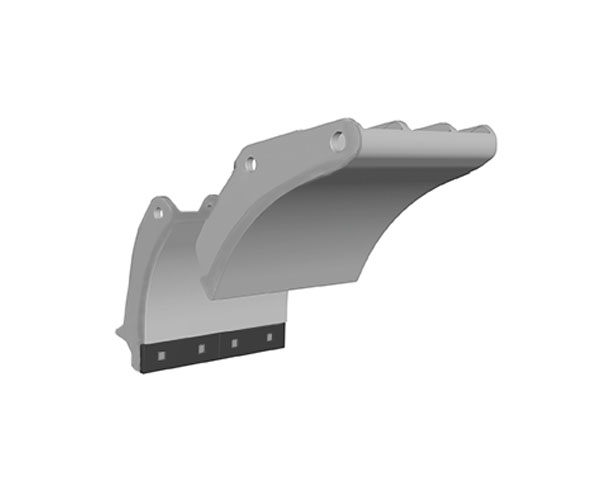

Wear strips and abrasion plates, also known as wear plates or side plates, crusher liners, wear liners, or liner plates, are essential components in various heavy machinery used for size reduction. These crucial parts protect the main structure of crushers, shredders, grinders, and chippers by absorbing the wear and tear caused during processing, thereby extending the lifespan and improving the efficiency of equipment used in industries like mining, quarrying, demolition, recycling, forestry, and biomass processing.

Here’s a deeper dive into how wear plates function:

Impact and Abrasion Resistance:

Wear plates are manufactured from high-strength, abrasion-resistant materials, such as manganese steel, chrome carbide, or composite materials. This robust construction allows them to withstand the constant impact and grinding forces associated with size reduction processes.

Protection for Key Components:

By absorbing wear, wear plates shield the underlying machine structure from damage. This translates to reduced maintenance costs and minimized downtime for repairs.

Optimized Performance:

By maintaining the integrity of the machine’s structure, wear plates ensure proper equipment alignment and functionality. This contributes to consistent performance and efficient processing throughout the machine’s lifespan.

Findeq understands the critical role of wear plates in maximizing the productivity and longevity of your size reduction equipment. We offer a comprehensive selection of wear plates, including:

- Customizable options to match specific requirements of machinery and applications.

- High-quality materials that ensure exceptional wear resistance and durability.

- Expert advice to help you choose the most suitable wear plates for your needs.

Investing in high-quality wear plates is a cost-effective strategy to safeguard your equipment, minimize downtime, and optimize your size reduction operations. Contact Findeq today to discuss your wear plate requirements and discover how we can help you achieve optimal performance and value.

Findeq – Your Trusted Partner in Recycling Equipment and Wear and Spare parts solutions:

At Findeq, we understand the importance of each component within recycling equipment like crushers, shredders, grinders or chippers. We offer a wide selection of high-quality wear plates, designed to be compatible with various machines. Our wear plates are manufactured with superior wear resistance in mind, maximizing their lifespan and minimizing downtime for replacements.

For more information on wear plates or any other wear and spare parts related needs, contact us or read more on this page explaining how to order wear & spare parts from Findeq.