WEAR & SPARE PARTS FROM FINDEQ

NEW FROM FINDEQ!

Wear & spare parts for your recycling equipment.

Keep your processing equipment running smoothly with Findeq’s selection of wear and spare parts for mobile and stationary crushers, screeners, shredders, grinders and chippers. Whether you’re in the mining, construction, demolition, recycling, or waste management industry, we understand the importance of keeping your equipment operational and maximizing productivity. That’s why we offer a wide range of high-quality original and non-original parts for a variety of leading brands at competitive prices.

✅ Order Parts, Anytime, Anywhere

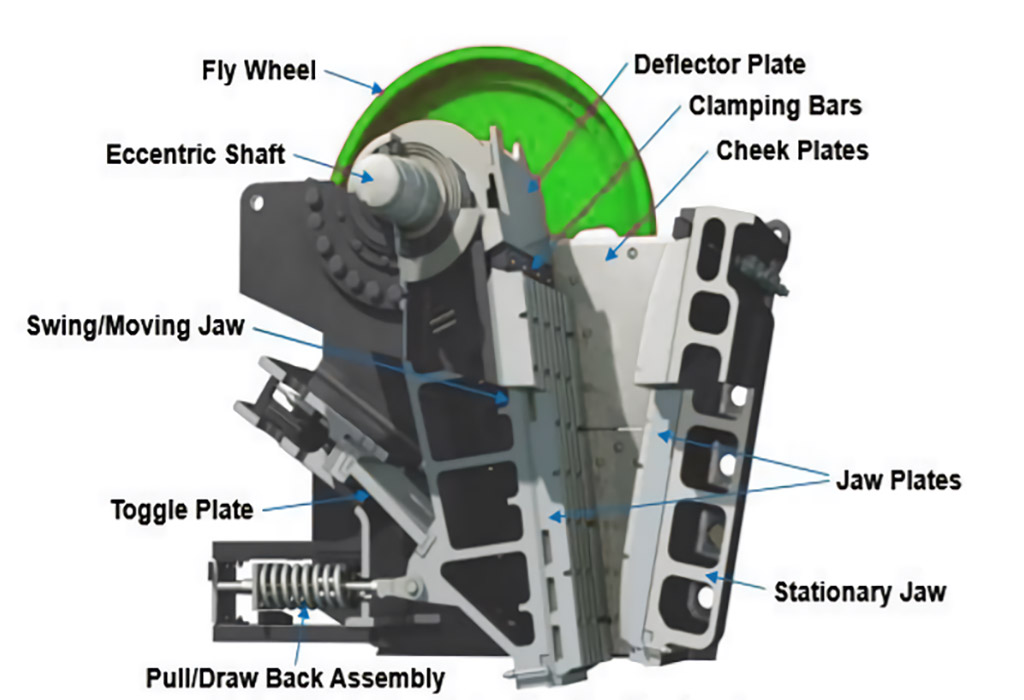

Jaw crusher parts: Jaw plates, toggle plates, liners, wedges, and more.

Cone crusher parts: Conecaves, mantles, bushings, and more components.

Impact crusher parts: Blowbars, impactplates, aprons and wear plates.

Screener parts: Screen decks, wear strips, tensioning systems and more.

Shredder parts: Shafts, hammers, knives, grates, counter combs and more.

Grinder parts: Grates, hammers, screens, and wear plates and more.

Chipper parts: Knives, Counterknife, Spiral shaft and more.

Are you in need of another machine or want to replace your current equipment? Click below to go to our equipment listings.

✅ Original and Non-Original Parts

Every customer has different budget considerations. That’s why we offer both original and non-original parts. Original parts are manufactured to meet the exact specifications of your equipment, ensuring optimal performance and longevity. Non-original parts provide a cost-effective alternative while maintaining high quality and functionality.

✅ Benefits of Choosing Findeq

Competitive prices with volume discounts, get the best value for your money. High-quality parts, ensure optimal performance and longevity of your equipment. Find parts for all your crushing, screening, shredding, grinding and wood chipper equipment. Get expert help finding the right parts for your machine.

Search for WEAR & SPARE PARTS✅ How to order your parts

To request or order your parts; in the top menu select your brand, then select the type of machine from which you need the parts.

You will see a selection of parts which we can offer you. Please fill in the form to send us your parts request.

You can skip the above steps by clicking the button below and go to the parts request form immediatly.

✅ Keep your machine running with wear and spare parts from Findeq!

At Findeq, we’re your one-stop destination for all your equipment and parts needs, offering a wide selection of high-quality components for renowned brands.

Choose from OEM or aftermarket replacement parts and enjoy quick delivery when you order online. Can’t find what you’re looking for? Reach out to our team for assistance!

Our focus is on delivering cost-effective solutions tailored to your specific requirements, whether you’re a distributor, end customer, or machine manufacturer. Count on us to keep your operations running smoothly.

Specializing in top-notch spare parts for Crushers, Screeners, Grinders, Shredders, Chippers, and other Recycling equipment, we ship parts of all sizes worldwide via Air or Sea for your convenience.

We understand the impact of downtime on material handling operations like yours – trust Findeq to keep you up and running hassle-free.

Metso, Sandvik, Sbm, Keestrack, Terex Finlay, Terex Pegson, Powerscreen, Nordberg, Kleemann, Hammel, Arjes, Doppstadt, Lindner, Vermeer, Zemmler, Eschlböck, Komptech, Terex Ecotec, Terex Evoquip, McCloskey, Anaconda, Telestack, Backers, Eggersmann, Haas, Terra Select, Siebotec, Hartl, Hazemag, MFL, Rockster, Extec, Gipo, Lippmann, Parker, Portafill, Prall-Tec, Rubble Master, SBM Wageneder, Svedala, Tesab, Rev, Tana, Untha, Zenith, Nordmann, Morbark

FIND Your Recycling Equipment, Wear & Spare parts on Findeq.com