Monoblock

Monoblock specifications

We offer a wide range of monoblocks for Horizontal Shaft Impactors (HSI) and Vertical Shaft Impactors (VSI) for your specific areas of use and applications. Our high-quality monoblocks are characterized by long service lives, a constant wear profile and high impact resistance (breakage resistance). We can also deliver monoblocks complete with impact plates. Request your (non) original monoblock in different thickness and steel alloys like wear-resistant electrocast steel alloyed with manganese an a special chromium addition on this page.

Complementary items to order if needed:

- Axle, shaft for monoblock

- Impact plates

- Grinding track

- Tension bolts and nuts (mounting material)

If you can not find the right items, please let us know in the request!

Looking for replacement parts for your recycling machine? We offer a comprehensive selection of (product) parts compatible with equipment from major brands like: Metso, Sandvik, SBM, Keestrack, Terex Finlay, Powerscreen, Nordberg, Kleemann, Terex Evoquip, Terex Pegson, McCloskey, Anaconda, Hartl, Hazemag, MFL, Rockster, Extec, Gipo, Lippmann, Parker, Portafill, Prall-Tec, Rubble Master, SBM Wageneder, Svedala, Tesab, Rev, Zenith

FAQ – Recycling Equipment. Also read our FAQ about the different types of crushers, screeners, shredders and chippers.

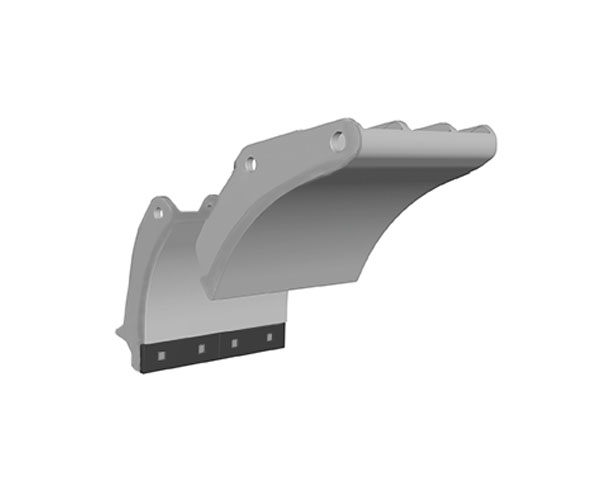

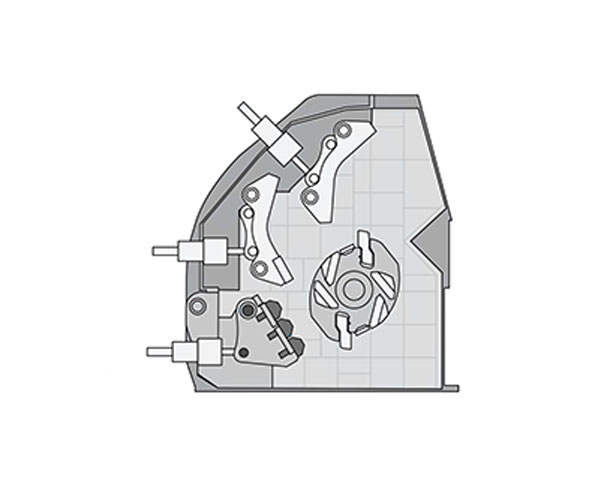

Monoblock: the monoblock in a crusher plays a crucial role in ensuring efficient material handling, consistent feeding, and protection of the crusher from damage. A monoblock casting essentially means these plates are manufactured as a single, solid piece. Monoblocks offer several advantages compared to welded or bolted designs.

Benefits: Increased Strength and Durability: Monoblock casting eliminates potential weak points like welds, resulting in a sturdier and more durable impact plate.

Benefits: Improved Impact Resistance: The solid construction of monoblock plates allows them to better withstand the high-impact forces associated with crushing operations.

Benefits: Reduced Maintenance: With no welds to break or loosen, monoblock plates generally require less maintenance compared to bolted or welded designs.

Additional grinding track: below the rotor axis can an additional grinding track be fitted that serves to increase the crushing ratio, improve the grain shape and increase the fracture surface

Findeq – Your Trusted Partner in Wear and Spare parts solutions:

At Findeq, we understand the importance of each component within an impactcrusher. We offer a wide selection of high-quality monoblocks, designed to be compatible with various machines. Our monoblocks are manufactured with superior wear resistance in mind, maximizing their lifespan and minimizing downtime for replacements.

For more information on monoblocks or any other wear and spare parts related needs, contact us or read more on this page explaining how to order wear & spare parts from Findeq.