Vibrating feeder

Vibrating feeder specifications

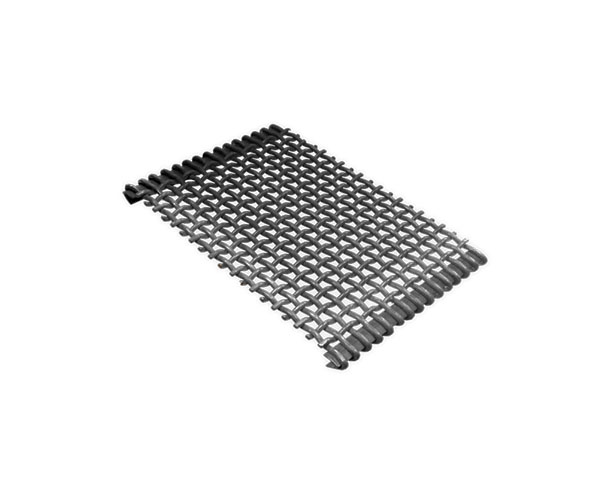

We offer a wide range of vibrating feeders for crushers. These vibrating feeders are located in the hopper for prescreening material for your specific areas of use. Our high-quality vibrating feeders are characterized by long service lives, a constant wear profile and a high impact resistance (breakage resistance). We can supply it as 1 complete unit or in separately available parts and in various steel alloys. Request your (non) original vibrating feeders on this page.

Complementary items to order if needed:

- Screengrid, complete

- Wear plates side and bottom

- Tension bolts and nuts (mounting material)

- Vibrating screen

- Screen mesh (different types)

- Clamping edge

- Outfeed plate

If you can not find the right items, please let us know in the request!

Looking for replacement parts for your recycling machine? We offer a comprehensive selection of (product) parts compatible with equipment from major brands like: Metso, Sandvik, SBM, Keestrack, Terex Finlay, Terex Pegson, Powerscreen, Nordberg, Kleemann,Terex Evoquip, McCloskey, Anaconda,, Hartl, Hazemag, MFL, Rockster, Extec, Gipo, Lippmann, Parker, Portafill, Prall-Tec, Rubble Master, SBM Wageneder, Svedala, Tesab, Rev, Zenith, Nordmann

FAQ – Recycling Equipment. Also read our FAQ about the different types of crushers, screeners, shredders and chippers.

Vibrating feeder: vibrating feeders are used in many types of crushers, such as jaw crushers, cone crushers, impact crushers, and gyratory crushers. They are used in various industries including mining, quarrying, construction, recycling, and aggregate production and ensure a steady and controlled feed of material into the crusher, improving overall efficiency, and reducing operational challenges.

Function in a crusher: in a typical crusher setup, the vibrating feeder first delivers the coarse material to the crusher unit. Some vibrating feeders can act as a preliminary screener. They have a section with a grid (called a grizzly) that allows smaller material to pass through before reaching the crusher. The fine material falls through the fingers of the vibrating feeder on the separate vibrating screen. It consists of a mesh or perforated plate that vibrates at a specific frequency. Material fed onto the screen is separated as the smaller particles pass through the openings, while larger particles remain on top. The fine graines will be seperated and finds it way outside the crusher via the outfeed/ side conveyor. The coarse fraction will be fed into the crusher unit.

Optimized Crushing: by providing a steady and controlled flow, the feeder helps the crusher work at its best, achieving consistent results and maximizing its capacity.

Reduced Wear and Tear: a regulated material flow prevents overloading the crusher, which minimizes wear and tear on its components. This translates to lower maintenance costs and a longer lifespan for the crusher.

Findeq – Your Trusted Partner in Wear and Spare parts solutions:

At Findeq, we understand the importance of each component within a crusher. We offer a wide selection of high-quality vibrating feeders, designed to be compatible with various machines. Our vibrating feeders are manufactured with superior wear resistance in mind, maximizing their lifespan and minimizing downtime for replacements.

For more information on vibrating feeders or any other wear and spare parts related needs, contact us or read more on this page explaining how to order wear & spare parts from Findeq.